The right blind rivet nuts for

your material.

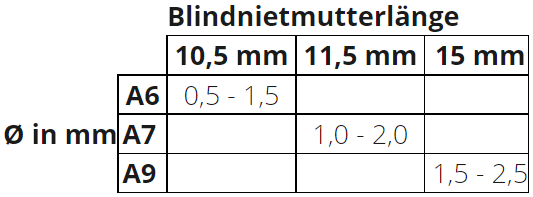

To be able to install a blind rivet nut, you need to know the material’s thickness and composition. Novus supplies aluminium and steel blind rivet nuts in various sizes for different applications.

Aluminium rivet nuts

For working with non-ferrous metals, plastics and lightweight materials.

Steel rivet nuts

For riveting steel sheets.

Advantages of riveted joints

- In comparison to screws, the advantage of blind rivet nuts is that no thread is made in any of the components.

- The connection is permanent and can only be broken by destroying it.

- It only requires access to one (usually the outer) side of the component.

- Setting a blind rivet nut is quick, easy and straightforward.

How to install

blind rivet nuts correctly.

We'll show you step by step how best to use

blind rivet nuts for blind rivet nut pliers.

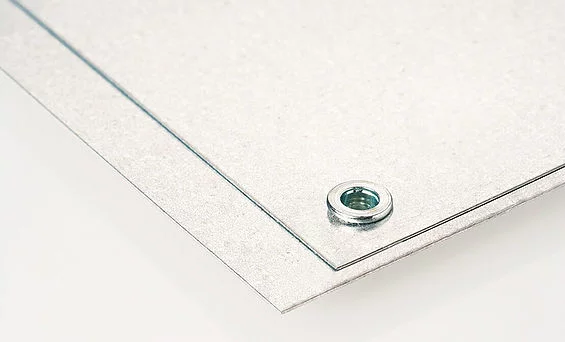

1 Measure

Measure the material thickness and select the appropriate blind rivet nut from the tables below.

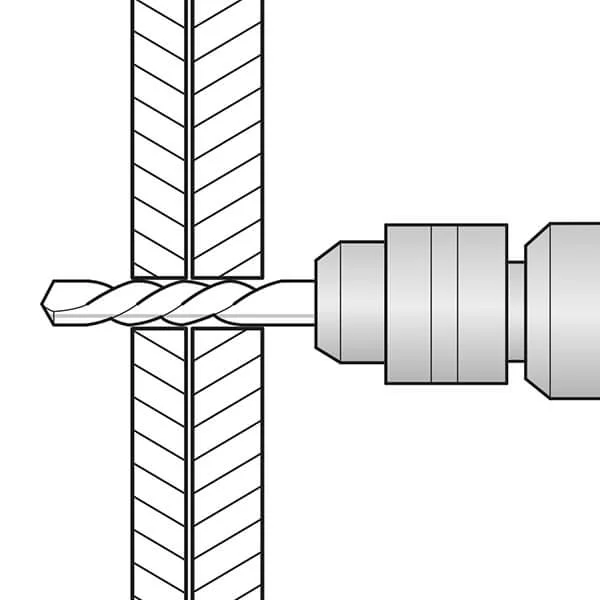

2 Drill hole

Drill a hole (0.1 mm larger in diameter than the blind rivet nut) into the part to be joined.

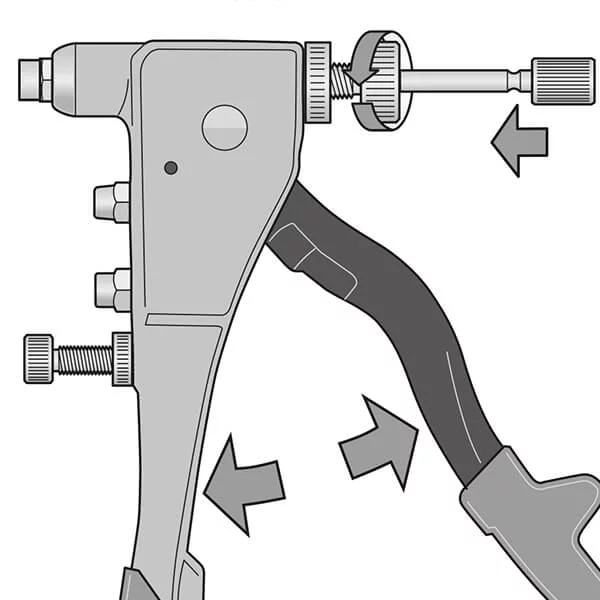

3 Insert threaded mandrel

Open handle catch and insert the threaded shaft.

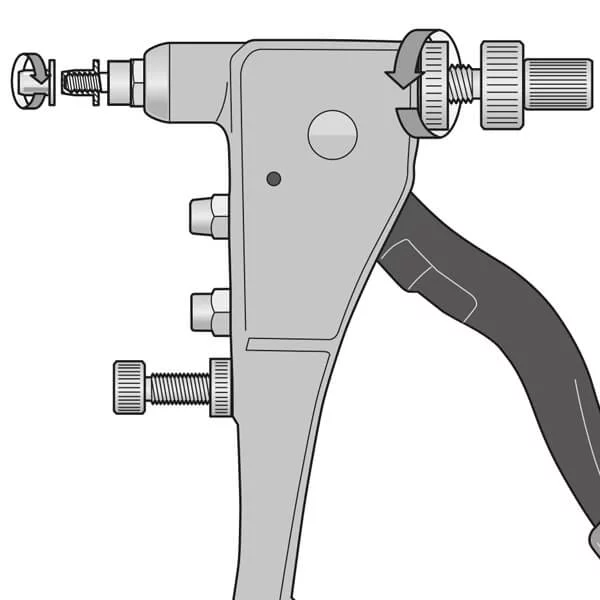

4 Screw on blind rivet nut

Screw the blind rivet nut flush onto the threaded mandrel.

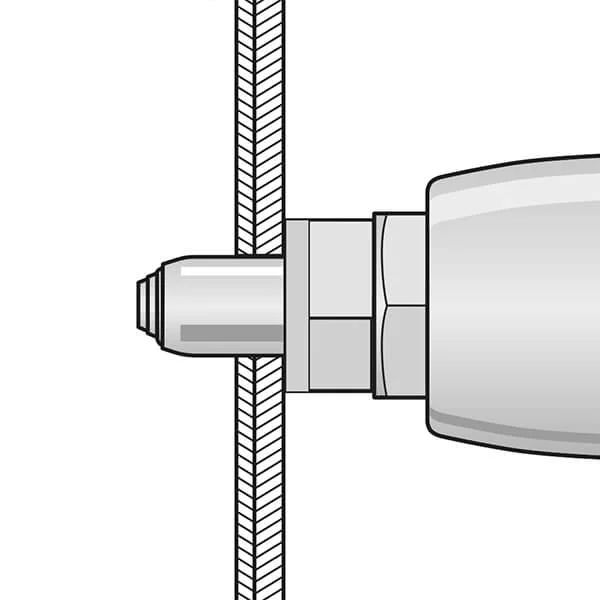

5 Guide through drill hole

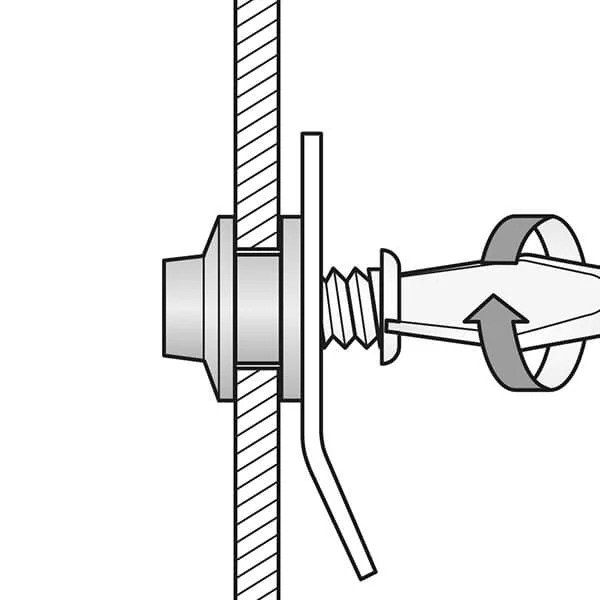

Guide the blind rivet nut through the drill hole, set the stroke limitation and press the handles together.

6 Attach object

Securely fasten an object to the blind rivet nut.

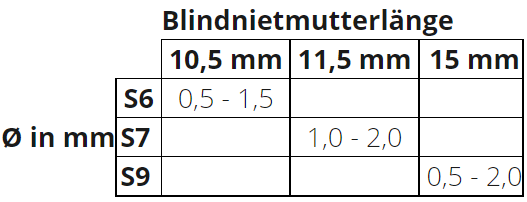

Blind rivet nuts are used here.

Fastening signs

Novus blind rivet nuts are ideal for attaching signs in places that are only accessible from one side.

Attaching a licence plate

Blind rivet nuts are also particularly suitable for DIY-ers. They make it easy to attach a moped insurance plate, for instance.

Attaching a nameplate

Signs can be attached quickly and easily to a locker thanks to the threads in the blind rivet nuts.

Material thickness.

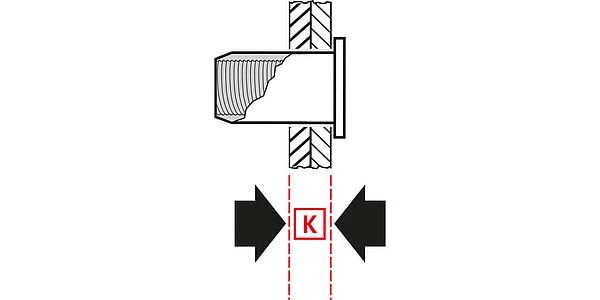

This overview shows which blind rivet nut has the appropriate material thickness for riveting (depending on rivet diameter and length). This dimension is generally referred to as the clamping length (K).

Blind rivet nut lengths

Tips

- To avoid contact corrosion, the workpiece and blind rivet nut should be made of the same material for metal joints.

- The diameter of the hole should always be 0.1 mm larger than the diameter of the blind rivet.